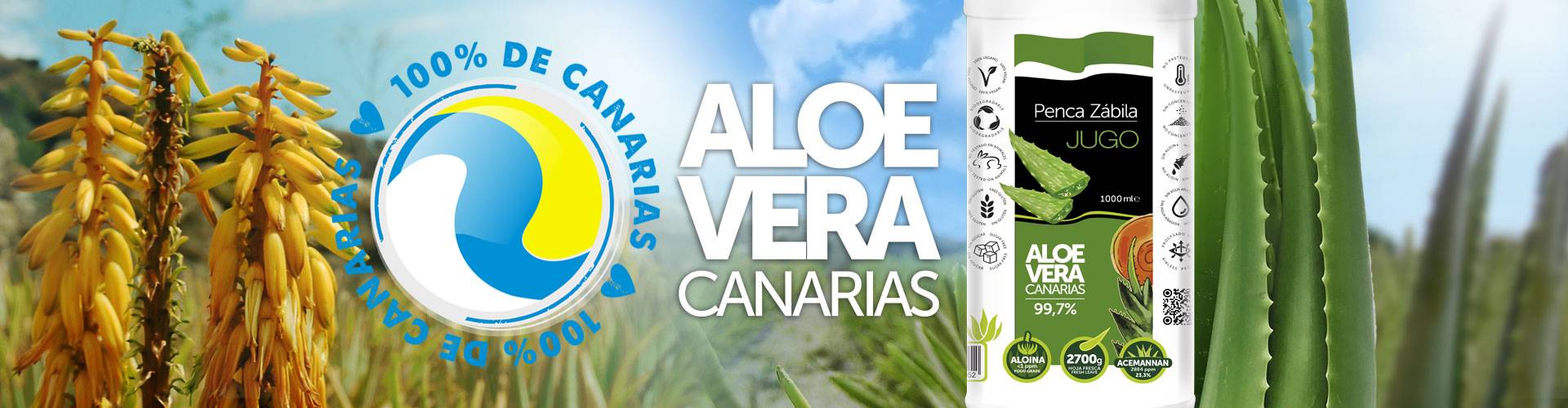

Aloe Vera Gel Penca Zabila 100ml 99.7%

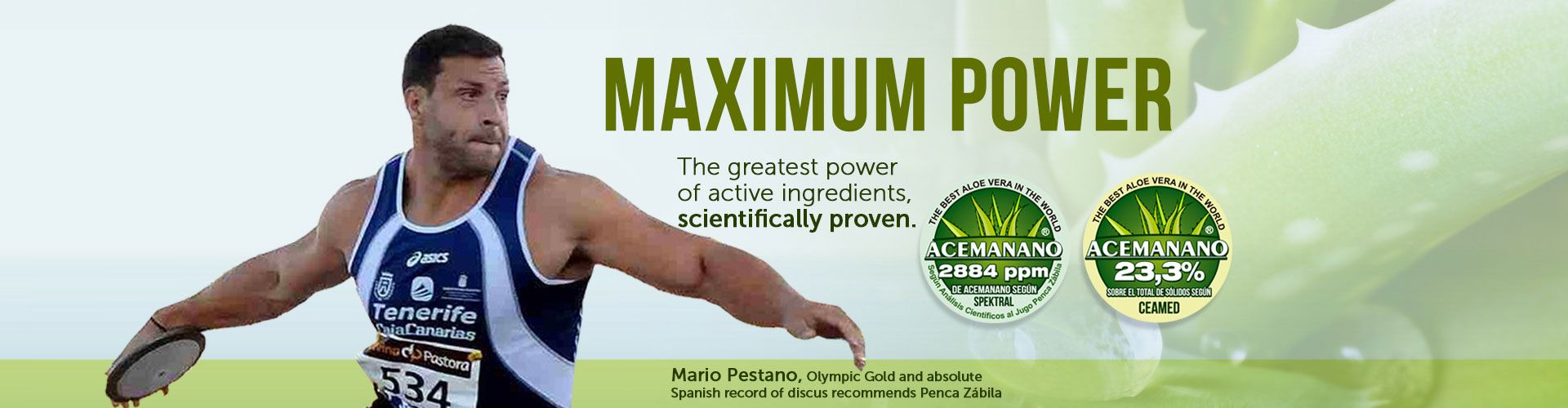

Aloe Vera Natural Gel 100 ml Net content: 100 ml Pure Aloe Vera Gel: 99.7% Fresh Aloe content: 2700g. of fresh aloe leaves within each liter Aloe Without Air: Integral processing in Air-Free Cold Tunnel Maximum Active Principles: 2884 ppm · 23.3% Acemannane No Dehydrated Powders · No Parabens ·...

- New